How Diamonds de Canada Reinvented Diamond Cutting

Benjamin King of Diamonds de Canada is helping tell the origin story and journey of natural diamonds.

When diamonds were discovered nearly 4,000 years ago, humans had yet to come across something they could not cut, bend, or shape to their will. Natural diamonds provided this unique challenge because they are the hardest natural substance on earth. It took hundreds of years to develop the first cutting techniques after the discovery of diamonds. The first diamond jewelry utilized diamonds only in their rough form. Only in the 20th century could we cut the round, brilliant diamond we know today.

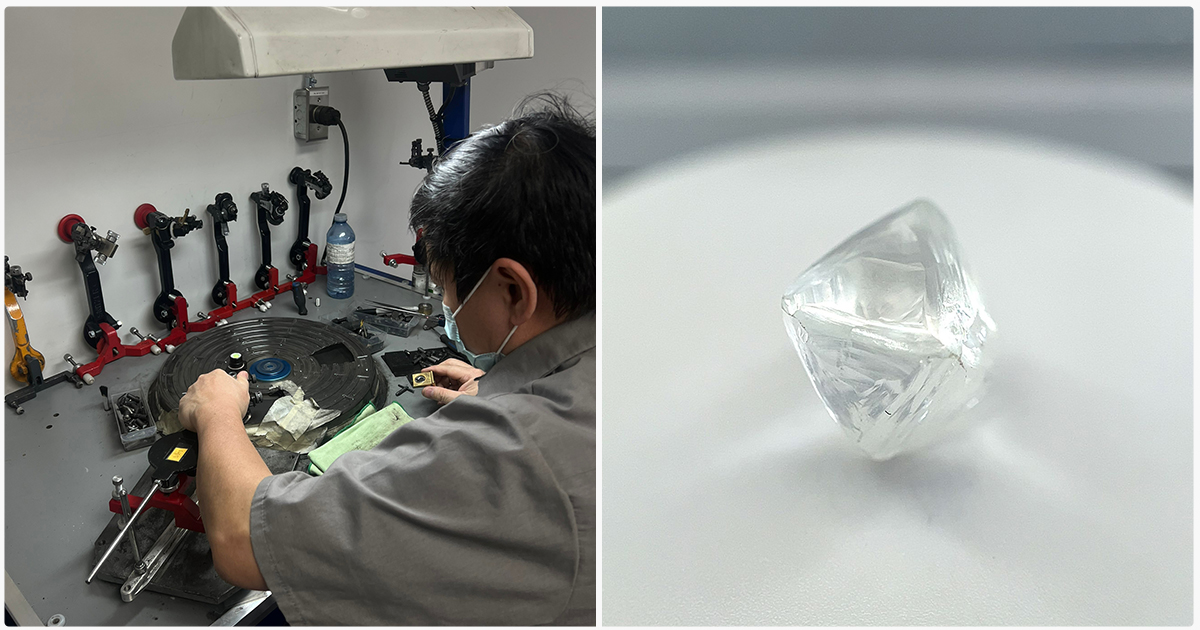

Natural diamonds’ unique properties make cutting them a process that is still done almost entirely by hand by skilled artisans with knowledge usually passed down for generations in areas of the world that came to specialize in the process. Outside of these areas, the lack of experts makes a diamond-cutting facility rarely feasible, let alone a facility in a remote part of the world where diamonds are discovered. This unique problem was one that Benjamin King of Diamonds de Canada was determined to solve.

Benjamin King was seemingly always enamored by natural diamonds. He would gladly share their story as one of the oldest things you could ever touch, born deep within the earth under extreme circumstances, their existence alone a miracle of Mother Nature. However, King was equally interested in the story of where each diamond was found, the uniqueness of diamonds from different areas, and the positive impact the diamond discovery had on the area and where it was found. This story was rarely known for each diamond once it had been cut. King may not have known it then, but he was destined to help change that.

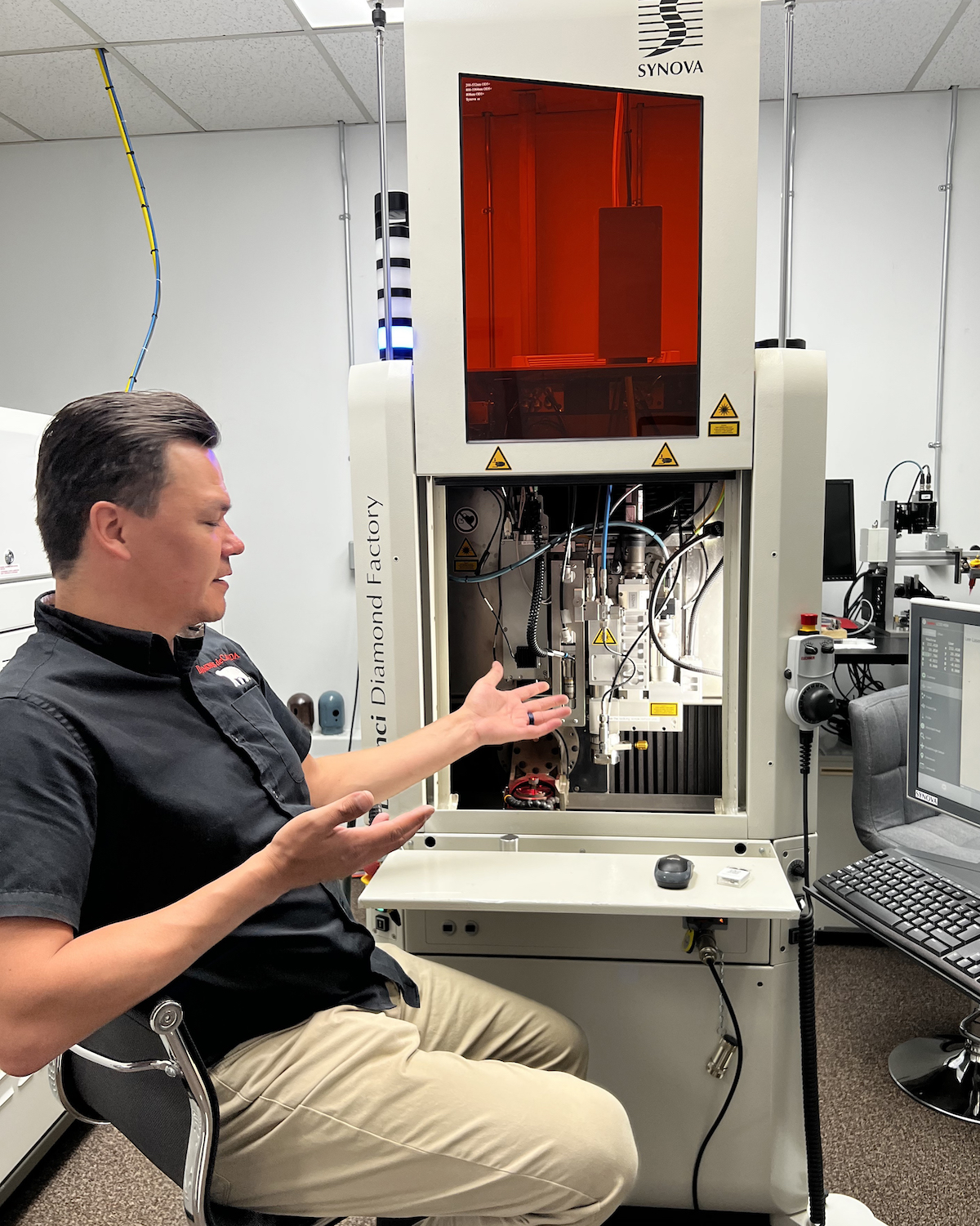

In 2019, King was working with a highly reputable diamond cutter and wholesaler when a company called Synova debuted a groundbreaking machine called the Da Vinci. This machine was the first of its kind to promise a nearly automated diamond-cutting process. Instead of years of apprenticeship or generational knowledge, the Da Vinci promised to simplify things. King’s first thought when he saw the machine was that it could now be more feasible to open a diamond-cutting facility in the remote areas where diamonds are discovered. If the cutter could get diamonds directly from the mine, cut them in the area, and sell them directly, it would be easier to track the process and tell the incredible story the way it deserves to be told. The difficulty of diamond cutting led to failed attempts at viable diamond-cutting facilities in areas like Canada’s remote Northwest Territories, one of the world’s largest diamond recovery areas.

King took it upon himself to meet with government officials in the Northwest Territories to introduce the new technology with hopes of invigorating diamond cutting in the area. At the time, King’s idea was not to open a facility himself; he was a matchmaker to the technology he thought could help the local area. However, the government officials liked the idea so much that they asked King to open a facility himself and apply for a unique program called the Approved Northwest Territory Diamond Manufacturer Designation. This program would allow a cutting facility access to rough diamonds from the source as long as they were cutting in the area. With government officials on board and his passion for telling the whole diamond story, King decided to go all in on the idea.

The Da Vinci machine that sparked this idea was undoubtedly an incredible piece of technology. Still, it was not a plug-and-play solution to transforming a rough diamond into a polished masterpiece. King worked for the next two years with programmers, engineers, and mathematicians to develop a process that would allow the Da Vinci to communicate and work with other pieces of equipment to create a first-of-its-kind technology-driven diamond cutting solution. The rough diamond can be analyzed, x-rayed, planned, and cut with minimal human intervention, leaving only the final polishing to be done by hand. King officially opened the Diamonds de Canada natural diamond cutting facility in Yellowknife, Northwest Territories, in 2021. By the Fall of 2021, King proved that his one-of-a-kind process worked.

Since the Diamonds de Canada facility didn’t rely on existing diamond-cutting experts, King could hire local and particularly indigenous residents of the Northwest Territories. The Operations Manager of the Diamonds de Canada facility is Derrick Sangris, a member of the Dene First Nation, a people indigenous to the area for over 30,000 years. Derrick’s son has recently joined, too, learning the process with his dad. Local mining, cutting, and employment mean that the most significant possible benefit percentage stays in the area where the diamonds are found.

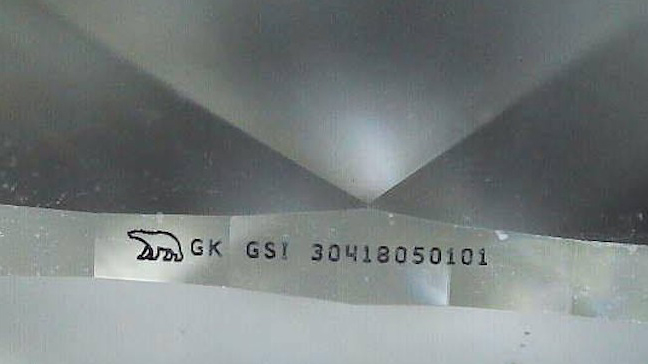

The government of the Northwest Territories was so thrilled with King’s ideas even before the facility was fully up and running, they asked him to apply to be the cutter of the famous Polar Bear diamonds. The Polar Bear diamond is a brand owned by the Northwest Territories that guarantees a diamond’s origin in the area. Each diamond is laser inscribed with the Polar Bear logo and a unique identification number. King decided if Diamonds de Canada were to revive the Polar Bear diamond, they would only cut 16,000 diamonds, tied to the number of polar bears left in Canada. Each of the 16,000 would be a minimum of 1.50 carats and hand selected as a perfect representation of the diamonds from Canada. Once 16,000 diamonds were sold, no more would ever be cut. With the Northwest Territories in agreement, these exceedingly special Polar Bear diamonds began being cut for the first time in nearly twenty years.

Beyond the Polar Bear diamond, every diamond cut by Diamonds de Canada is fully traceable to the exact diamond mine where it was found. Since every natural diamond is entirely one of a kind, its unique internal pattern is scanned and issued a code, then placed on an incorruptible blockchain ledger, effectively making a unique NFT of the diamond. Without getting overly complicated, this ensures the diamond and all its details are always traceable, with proof of ownership.

Diamonds de Canada’s unique way of doing things could be a blueprint for creating viable and more sustainable diamond-cutting facilities in other areas where diamonds are discovered. Every natural diamond has a remarkable story, and with Diamonds de Canada’s process, not a piece of their story is lost, even as the diamond is passed down from generation to generation.